FOR IMMEDIATE RELEASE:

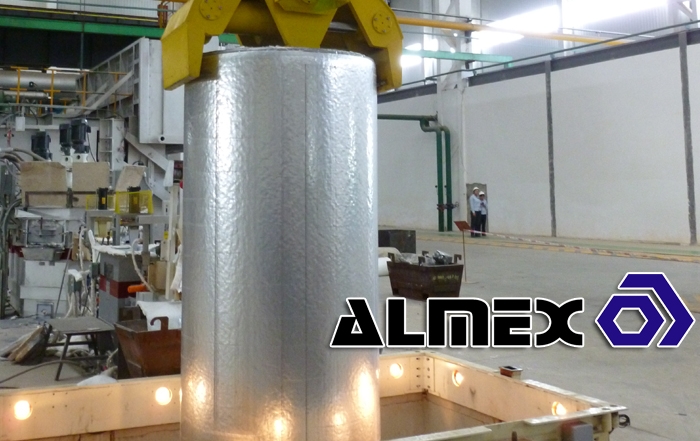

Buena Park, California – August, 2013 – Affirming its position as the industry leader in advanced aluminum direct chill (DC) casting technologies, Almex has announced the successful commissioning of the world’s latest billet mold measuring 52” (1320 mm) diameter. The casting, which was conducted at an undisclosed customer’s location, weighs over 210 lbs per linear inch. The commissioning of the mold was conducted over the course of one week and included both commercial aluminum alloys as well as specialty aerospace grade alloy chemistries in the 2xxx series family. Prior to Almex’s recent casting of this super-large diameter, the record was previously held at 48.5” (1230 mm) by a Russian plant.

The commissioning was conducted on a casting line composed entirely of Almex’s products including the LARS® degassing and purification system, FILTREX™ ceramic foam filtration, MEGA™ DC casting machine, and CASTRIGHT II™ automated control system.

Billets in such super-large diameters present interesting challenges throughout the casting process. Almex metallurgists and seasoned casting operators carefully developed the process recipe and procedures to account for those parameters which are most critical in the safety and performance of super-large diameter billet casting. The finished product of this work allows for Almex’s customers to utilize casting recipes which are custom tailored for their plant while ensuring casting safety, simplicity, and performance.

The applications for such large diameter castings are even more unique. Primarily used in the rolling of large forged rings, super-large diameter billets provide the raw material for airframe and space system components. The benefits of monolithic structures, versus multi-part assemblies, are well known in the aerospace communities. Accordingly, aerospace material requirements have become more demanding with increased payloads and aircraft size. More than ever, Almex’s EXCEL™ billet tooling systems are responding to such industry needs and can even be retrofitted to modernize existing casting installations.

Download a PDF version of this article, here.

About Almex USA