SAFETY, PERFORMANCE, SIMPLICITY.

When technology is based on these three fundamental values, innovation and development thrive:

empowering us to elevate the craft and science of aluminum casting, equipment engineering, and process design.

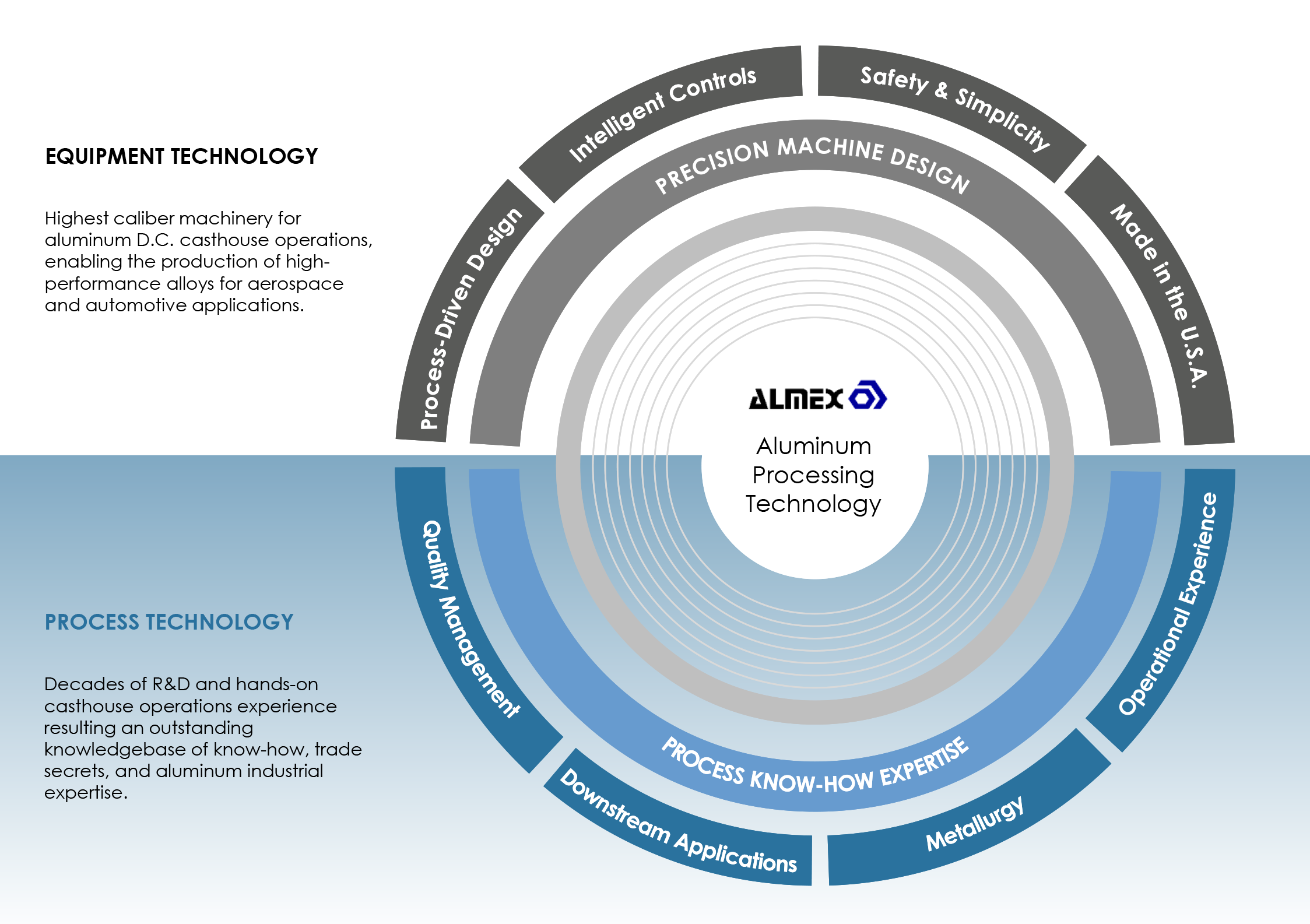

Almex USA has been the independent technology provider of high-performance aerospace, hard alloy, and soft alloy aluminum casting systems and related equipment for over 25 years. Having invested deeply into research and development efforts in the fields of metallurgy, equipment design, and process safety, the company holds its intellectual property achievements through a variety of patents, trade secrets, copyrights, and trademarks. Almex holds over 25 patents in various countries worldwide, covering over 700 patent claims.

Several Almex engineers and R&D professionals each have 30+ years of hands-on experience in process technologies relating to advanced aluminum alloys covering melt treatment, casting, rolling, extrusion, and specialty thermo-mechanical processes that have enabled the company to develop its vast library of recipes, trade secrets, and know-how that complement the core competency of casting. Such critical process knowledge has allowed Almex to provide its know-how and technology on a unique license basis along with experiential knowledge of value-added downstream processing paths to some of the most strategic aluminum facilities worldwide.

One of the most value-enriching components of Almex’s offerings remains its approach to “Furnace to Finish™” Solutions. Under this well-recognized slogan, Almex is uniquely able to provide a guarantee to its customer’s customer’s finished product; attesting to the worthiness of downstream processed products manufactured the ‘Almex way.’ This wholesome approach to engineering and product delivery is what enables the company to hold the record in casting both the world’s largest billet and the world’s largest slab: in both conventional and high-performance hard alloys.