Almex FILTREX™ Ceramic Foam Filtration (CFF) System employs dedicated ceramic foam filter(s) to remove inclusions which are generated between the refining system and the mold table. The ability of the ceramic foam filter to capture these inclusions is critical to maintaining a clean ingot during the solidification of metal. Accordingly, the quality and the productivity in downstream operations such as forging, extruding, and rolling are guaranteed.

At Almex, the continual quest is to ensure that our customers receive the best technology available on the market to produce the highest quality billet, slab, or ingot for their customers. Our guarantee does not stop with our customer, but continues to our customer’s customer! Our technology guarantees conformance of casting quality for the most critical end-product applications.

Three filtration modes operate in the FILTREX™ system:

- Particles larger than the pore size are captured at the top of the ceramic foam filter

- Smaller particles are captured on the filter cake created by the larger particles

- Finer particles are captured within the pores in the filter

When used in combination with our Liquid Aluminum Refining System, or LARS™, our guarantee is a highly inclusion-free product for forging, extruding, and rolling operations.

Primary System Components

-

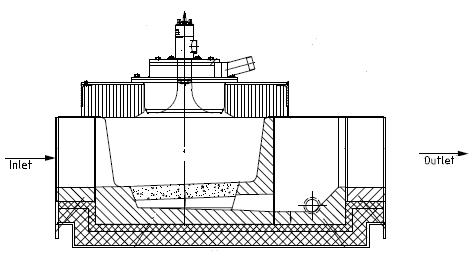

Filter Unit – Built to withstand the rigors of the aluminum cast house environment, the Almex FILTREX™ unit is fabricated using structural steel plate and is fully welded. The insulating lining is designed to minimize the heat loss through the walls of the filter unit and to make for easy emptying and draining of the unit. The size of the filter unit is dependent on the flow rate of the aluminum into the casting table. The design also considers the ease of emptying and draining of the unit after a cast and incorporates the concept of adjustable leg heights.

-

Refractory – Design characteristics of the refractory include low thermal conductivity, good thermal shock resistance, dimensional stability at operating temperatures, high mechanical strength throughout the refractory thickness, excellent non-wetting properties, easy to clean, low hydroscopic, and lower density than molten aluminum.

-

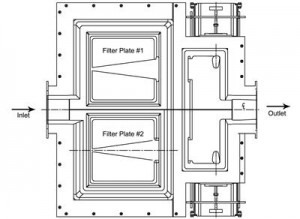

Ceramic Foam Filter – Made from alumina, the ceramic foam filter maintains its high strength and its excellent resistance to chemical wear through the cast. The pore network within the filter provides a large surface area for inclusion entrapment. Filter dimensions range from 15, 17, to 23 inches and pores size from 20 to 60 ppi. For high cleanliness requirements, double filters are available having two pore sizes.

-

Expandable Gasket – Tight contact with the filter box is achieved with an expandable gasket which creates a contact seal preventing leaking of the molten aluminum between the filter and the filter box.

-

Preheating Devices –Preheating of the ceramic foam filter and the box is achieved by efficient burners. These pre-heating burners meet international standards and efficiently heat the filter and filter box to prevent freezing at the start of the cast. Even and uniform heat dispersion is achieved by the Filtrex lid which is pneumatically actuated and heated electrically. Both advantages ensure complete heat priming and sealing of the expandable gasket.

-

Control Panel – A control panel is provided with the necessary switches and controllers for control of the preheating, for feedback of the thermocouple and alarm signals, and for the inert atmosphere cover gas (if used).

Our Guarantee

-

Performance Guarantees are based on use of a 40 ppm filter element, supplied by a reputable international supplier.

-

For these values to be valid, the FILTREX™ filtration system must be operated in conjunction with a LARS™ degassing and purification system supplied with the process gas requirements as stated in the LARS™ Performance Guarantee requirements.

-

For metal flow rates less than 30 tons per hour, the performance criteria will apply for use with a single filter module per casting line. Above 30 tons per hour, the performance criteria will only apply when using two filter modules installed in the line simultaneously.

Filtration Performance Guarantees are as follows:

-

Inclusions ≥ 50 µm are captured by the CFF with 99.7% guarantee

-

Inclusions < 50 µm and ≤ 20 µm in size are captured by the CFF with 99.3%

-

Inclusions < 20 µm in size are captured by the CFF with 99.0%

-

Guarantees for > 5 µm in size inclusions is significantly varied with amount of salts in the metal streams. But the number is generally assumed to be 97.0%