The MEGA™ DC Casting Machine plays a critical role in the casting process. It supports the entire weight of each cast while keeping tight control over speed and position. Moreover, it must maintain pinpoint accuracy over years of reliable service.

As the leading supplier of hard alloy casting equipment, Almex understands the rigorous demands placed on casting machines. The Almex MEGA™ DC casting machine not only meets these demands, but it does so while maintaining the highest levels of safety, performance, and ease of operation.

Almex application engineers customize each one of our casting machines for each application, taking into consideration weight loads, cast length, and other process details.

MEGA™ Casting Machine delivers the precision needed for superior DC Casting.

Primary System Components

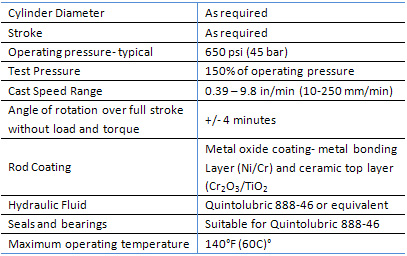

- Casting Cylinder – Almex offers two styles of internally guided casting cylinders: single-acting (gravity enabled) or double-acting (positive pressure). The best choice depends on the cast product configuration and alloy. Both styles employ a proprietary ceramic rod coating and the very latest technologies in reduced bearing friction and leak-free, low-friction sealing. Almex’s MEGA™ DC casting machines are custom designed and manufactured to fit the specific application’s operating needs.

- Torque Limiting Device – The torque limiting system protects the internal cylinder anti-rotation mechanism. This break-away torque limiting device offers protection against damage caused by external forces or by foreign objects that may enter the casting pit.

- Platen – The platen is designed to support the starting head base with the necessary strength and rigidity to ensure proper casting operation. Platens are constructed from heavy duty blanchard-ground structural steel components.

- Water System – Includes controls and hardware for supply water, returnwater, water cooling, and water quality management systems.

- Hydraulic Power Unit – The hydraulic power unit, or HPU, includes a fluid reservoir, pumps, valves, and industry-leading valve manifold. It is provided in a skid-mounted configuration ready for anchoring to the floor, and is fully wired and piped to convenient interfaces for simple field connections.