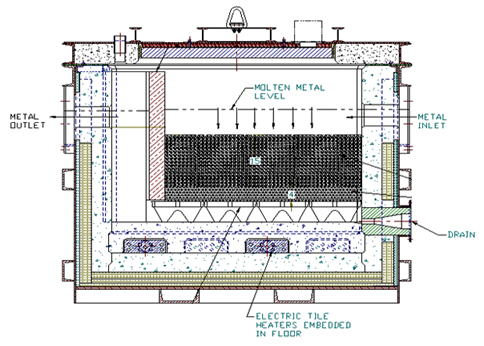

An alternative type of FILTREX™ filtration device is Almex’s Deep Bed Filter, or DBF. Almex’s DBF vessel utilizes a three-layered filter media consisting of tabular alumina balls on top of thick bed of crushed tabular alumina (called fines), and a final layer of tabular alumina balls. As the molten metal flows through the filter media, particulate impurities are trapped within the interstices of the fines. The balls prevent fines from entering into the molten metal stream.

The Almex DBF is electrically heated to maintain and control the metal temperature inside the unit during casting and between casts. Graphite tiles with inserted heating elements are installed in the vessel’s floor refractory and radiant heating elements are installed in the electrically heated cover. All necessary temperature and high-limit controls and monitoring instruments are contained within a control panel. Also provided is a natural gas fired pre-heat cover, which is used in place of the electrically heated cover, to facilitate accelerated heat-up of new filter media.

To prevent oxidation of the aluminum a positive pressure of an inert cover gas, argon, is maintained above the molten metal surface. Nitrogen purge gas is injected into the floor heater tile enclosures to prevent oxidation of the graphite tile material and corrosion of the heating elements. An Inert Gas Control Panel contains the controls necessary to regulate these gas flows and pressures.