FOR IMMEDIATE RELEASE:

Long Beach, California, USA – February,2012 – A highly automated and safety-conscious aluminium DC slab casting plant is a dream come true according to plant owners, managers, and casting operators. This dream has become a reality for the staff of one plant in China where Almex’s industry-leading equipment, process technology, and automation have proven their value in performance and safety.

Almex is proud to announce that its most recent project, a complete turn-key plant installation in Xuzhou City, China, has been commissioned with great success. The 75 metric ton slab casting plant, owned and operated by Shanghai Datun Energy Resources Co., Ltd., is configured to process aluminum scrap and primary ingot and use cutting edge processes in direct chill casting of 5 strands of slabs in 1xxx, 3xxx, 5xxx, and 8xxx series aluminum alloys in nine different ingot sizes.

The plant has been equipped with Almex’s patented LARS® degassing systems, FILTREXTM ceramic foam filtration, MEGATM DC casting machine, CASTRIGHT IITM complete system automation, Almex’s comprehensive water management system, complete process technology and know-how, and also Almex’s DBF for the processing of high purity aluminum for foil stock applications.

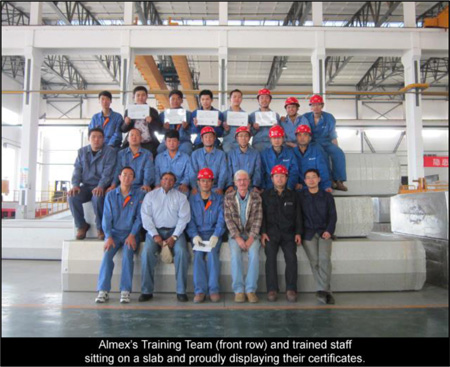

The project’s success is closely attributed to the carefully coordinated training provided by Almex. Classroom seminars, in addition to round the shifts hands-on training in the field, were provided to the greenfield site’s personnel.

The CASTRIGHT IITM automated casting control system, developed by Almex, regulates the entire casting operation, integrating Allen-Bradley PLCs with HMI interface designed with InduSoft Web Studio and Visual Basic 2010 to ensure an intuitive and all-inclusive control system. Casting information is used to print casting reports that include graphs of the casting processes as well as all discrete information entered by the operator. Finally, the stored data is optimized to reduce the actual size of the database so that casting data can be stored in the database for the entire life of the casting system.

Almex prides itself on delivering casting systems that are cleaner, simpler, flexible, and more cost-effective and works hard to stand by one of their mottos, “Simplicity that Works.” In order to maintain such high standards, Almex provides a software solution that offers maximum functionality in maintaining and monitoring its casting equipment.

Download the PDF version of this article, here.